Ground Networks & Data Distributions

Ground Networks & Data Distributions  Data Processing & Visualisation

Data Processing & Visualisation  Data Analytics, Insights & Applications

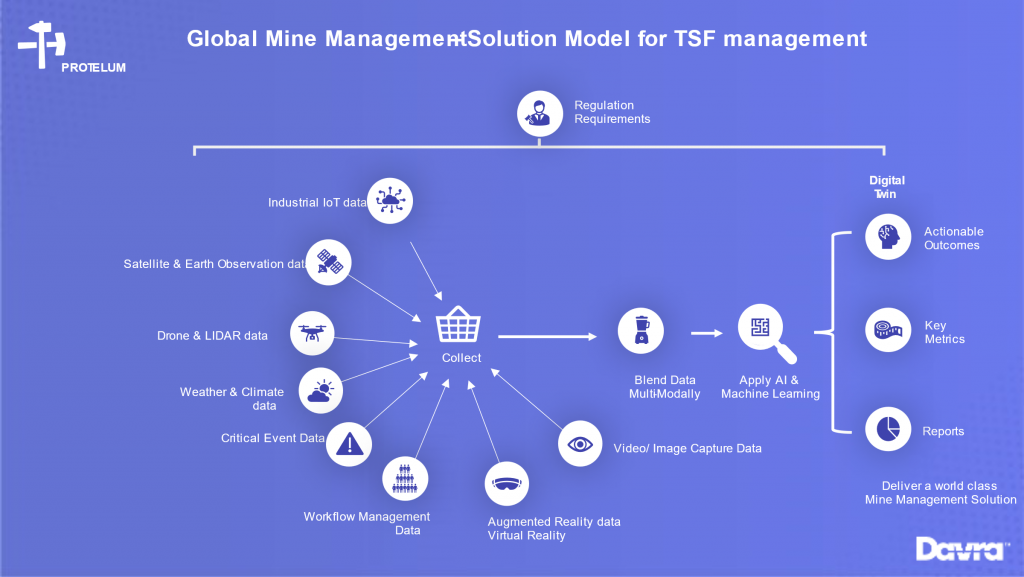

Data Analytics, Insights & Applications Operative, infrastructural, and environmental safety are key priorities at mine sites. Mine operators and regulators need to systematically identify risks inherent to underground and surface operations on a continuous basis. The industry needs to employ technologies that can ensure the ongoing operation of critical controls, to generate insights regarding the effectiveness of mining operations To date, monitoring technologies employed in mine installations tend to be bespoke, siloed solutions that require significant “human-in-the-loop” resources and manual data analysis.

The Protelum solution leverages Davra’s industry leading Industrial IoT platform to consolidate all data sources by combining data from legacy data silos into a single unified data source. This allows cross pollination between data sources facilitating analytical methodologies on combined datasets.

There are common thematic problems in managing mines which require continuous, iterative monitoring and management, specifically in the areas of water management, ground stability and environmental impact monitoring. The industry needs solutions that can work with hard and soft sensors and other monitoring technologies to provide continuous assurance of critical processes with less reliance on physical data capture and manual processing. Monitoring processes are important to industry and public stakeholders alike and are coming under increased social scrutiny and regulatory control. There is no “single pane of glass” mine management system that can collate hard and soft operational data, blend the data multi-modally with Satellite, EO and GNSS data and apply AI and machine learning to deliver key operational metrics and actionable insights. The PROTELUM project aims to deliver such a system.

The target customers are as follows:

Th solution targets the global Mining Industry

Davra is developing a cloud-based platform to monitor and manage mine tailing’s storage facilities (TSF). The solution merges EO, drone and LIDAR data with available terrestrial data to show changes in the TSF in order to manage its safety and to forecast potential physical breaches or environmental regulation breaches. It is the aim of the project that the solution developed under the activity can be used globally in a variety of mining environments.

The solution is being designed to meet the ICMM regulation for TSF monitoring. The collection of data from multiple sources and the associated classification of this data in terms of compliance and risk management ensures the solution will fit with the “good engineering practices for tailings management” as defined by the ICMM. Data is validated from its source and the system provides GDPR and ISO 27001 data security compliance.

In terms of automating mine tailings storage facilities, Petroleum can employ interferometric SAR in the analysis of tailings storage facilities, tailings beachheads and general ground stability. This data when linked to GNSS referenced LIDAR and other terrestrial data offers a means of analyzing live data and developing predictive models which can be used to ascertain regulatory and environmental compliance.

The project commenced on the 23rd of August 2022, with milestone #1 occurring on Feb 28th 2023.